Digital Manufacturing Sites and Production Lines Monitoring

It's crucial to connect multiple manufacturing sites and production lines seamlessly. With our Unified Manufacturing Platform, you can achieve centralized visibility across your enterprise, gaining real-time data and insights.

Monitor Multiple Production Sites

Effortlessly connect multiple manufacturing sites and production lines to our smart factory software, enabling you to access real-time data and insights. By consolidating information from various locations, you can enhance operational efficiency and make informed decisions.

Improve Your Entire Manufacturing, Not Just One Machine

Optimizing manufacturing operations requires a holistic approach. Our Smart Manufacturing Platform empowers you to identify bottlenecks, predict issues, and take proactive measures to optimize operations across your entire manufacturing ecosystem. By leveraging advanced analytics and machine learning, you can improve efficiency and optimize processes.

Remote Access Anytime, Anywhere

Tracking site-wide key performance indicators (KPIs) is crucial for optimizing performance and maximizing profitability. With our digital Manufacturing Platform, you can easily monitor KPIs remotely, eliminating the need for time-consuming site visits. Access critical data from any location and make data-driven decisions to drive operational excellence. Taking control of your manufacturing operations is essential in today's digital age. By adopting our digital factory software, you can collaborate seamlessly with teams across your business units, harness the power of real-time data and insights, and unlock the full potential of your manufacturing sites and production lines.

Remember, our Advanced Manufacturing Platform is designed to optimize your operations, enhance efficiency, and drive continuous improvement. Embrace the digital transformation of manufacturing and unlock new possibilities for success.

Mastering Multi-Site Monitoring: Harness the Power of Modern Manufacturing Software for Remote and Multiple Production Sites. Check Dashbaords here.

Remotely Monitor Multiple Manufacturing Sites

Connecting multiple manufacturing sites and production lines with a Unified Manufacturing Platform allows for remote monitoring and optimization of performance across all your sites. With a simplified remote manufacturing management approach, you can gain a comprehensive view of your enterprise's key performance indicators (KPIs) from anywhere in the world.

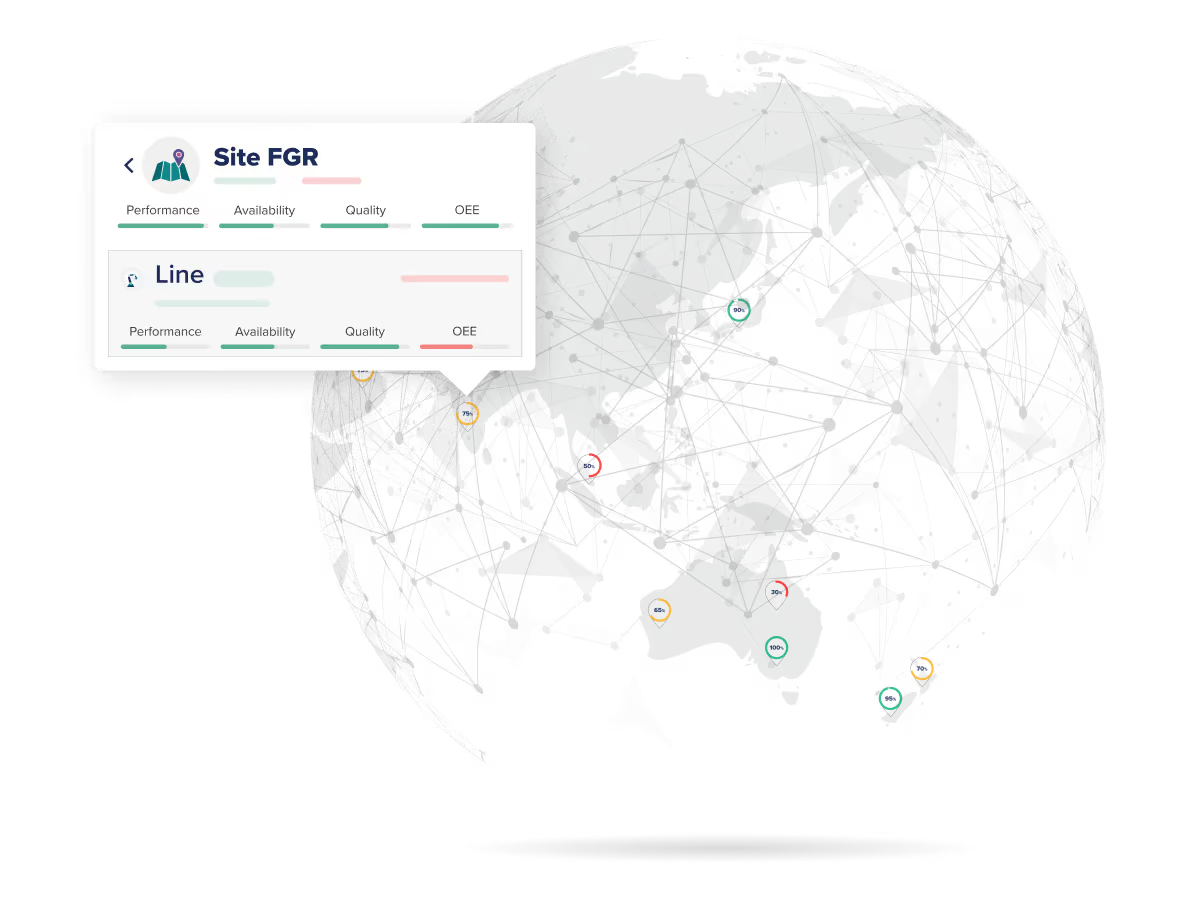

Get a Bird's Eye View of Your Manufacturing Sites in Seconds

With our Unified Manufacturing Platform, you can effortlessly access a bird's eye view of your manufacturing sites. Simplify remote manufacturing management and optimize performance by monitoring all KPIs of your enterprise from a centralized dashboard.

By connecting once, you gain real-time insights into production status, quality metrics, and other essential data, saving valuable time and effort.

A Real-time Unified View of Your Manufacturing Enterprise

Unlock the full potential of your manufacturing operations by leveraging our Unified Manufacturing Platform's data-driven insights and optimization capabilities. With real-time data at your fingertips, you can make informed decisions faster, ensuring timely responses and proactive actions.

Stay ahead of the curve and drive continuous improvement by monitoring performance, identifying trends, and implementing targeted strategies across your manufacturing sites.

Remotely monitoring multiple manufacturing sites with our Unified Manufacturing Platform offers unparalleled visibility and control over your operations. By harnessing the power of data and leveraging advanced analytics, you can optimize performance, improve efficiency, and drive success across your entire enterprise.

Remember, our smart factory software enables you to seamlessly connect manufacturing sites, gain real-time insights, and make data-driven decisions to unlock your manufacturing enterprise's true potential.

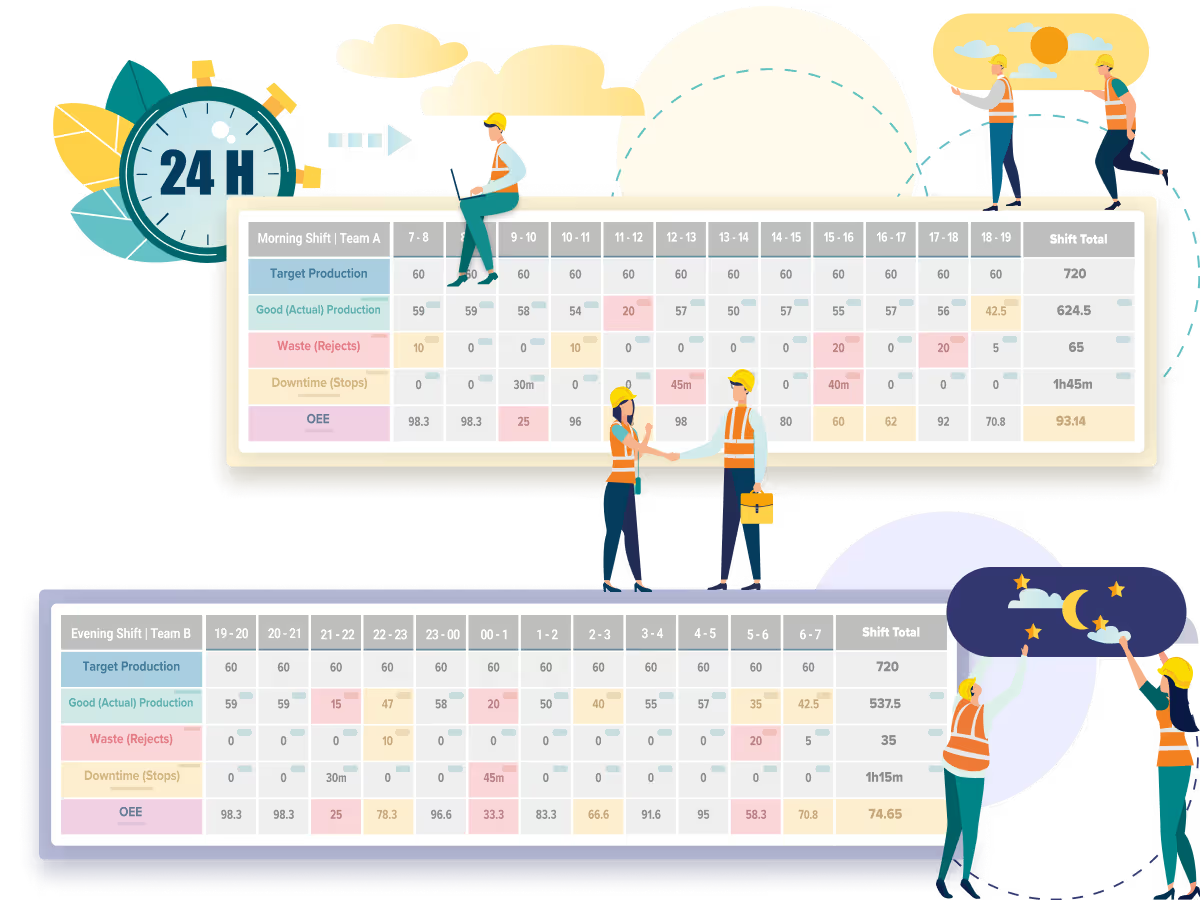

Seamless Shift Transitions: Revolutionizing Manufacturing with Automatic Shift Handover Technology. Read more on this feature.

Transform Your Shopfloor Landscape across all Manufacturing Sites into a Unified Production Hub

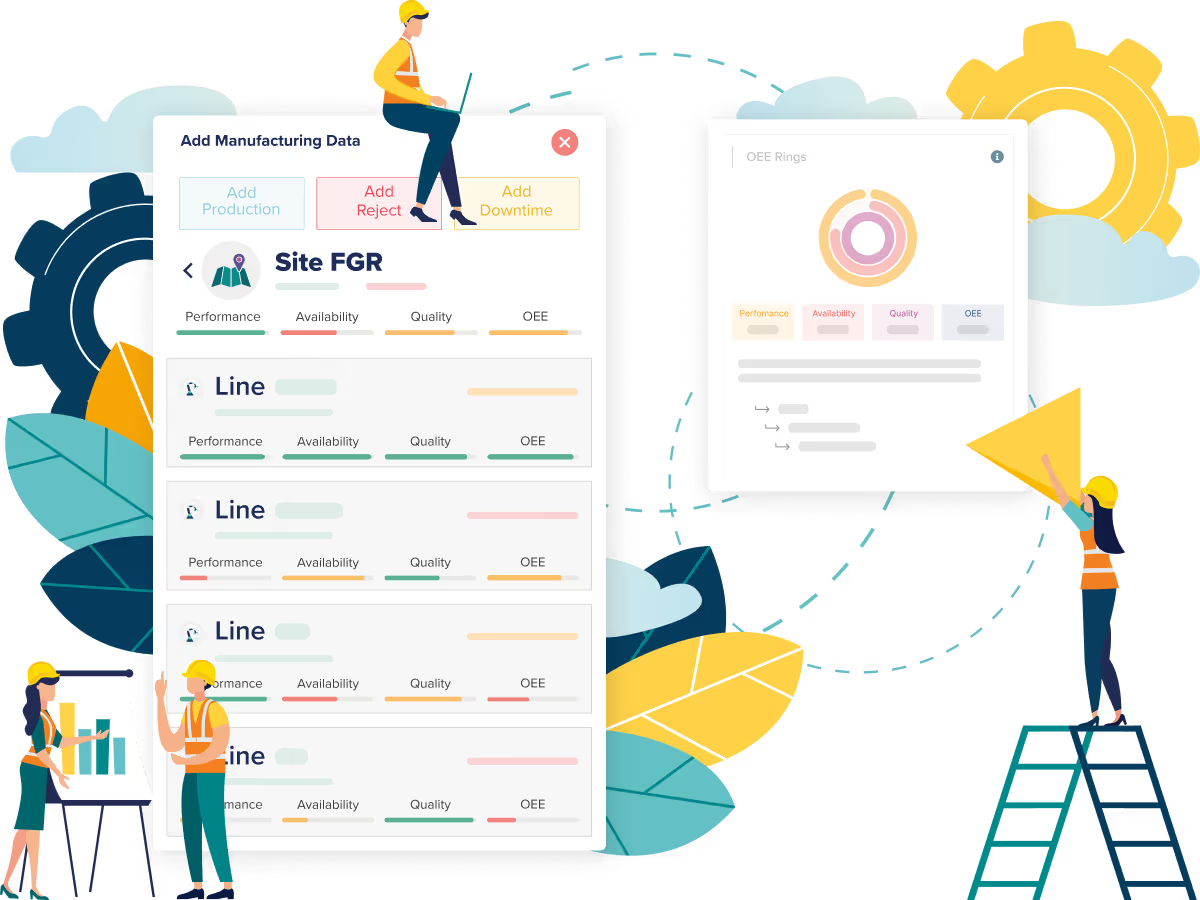

Continuing our exploration of optimizing manufacturing operations, it's time to transform your shopfloor landscape across all manufacturing sites into a unified production hub. By leveraging our advanced Manufacturing Execution System (MES), you can set key performance indicators (KPIs) for your entire factory or multiple factories and monitor them in real-time using a centralized manufacturing dashboard.

Set KPIs for Your Entire Factory or Multiple Factories

With our unified production hub approach, you can establish KPIs for your entire factory or multiple factories. This allows you to define performance metrics and targets, ensuring consistent monitoring and benchmarking across your manufacturing sites.

By utilizing a centralized manufacturing dashboard, you gain real-time visibility into production data, enabling proactive decision-making and optimization.

Now, regardless of your location or the time, you can monitor all your manufacturing sites. Our advanced factory software provides real-time alerts and notifications, empowering you to stay on top of any issues even when you're not physically on-site. This remote monitoring capability ensures proactive response and minimizes downtime.

- Improve Line Production Rate: Prioritize enhancing the performance of the least productive line to bring all lines up to a more consistent level of productivity.

- Reduce Line Backlog Time: Optimize assembly line workload and minimize backlog time to improve overall operational efficiency.

- Schedule with Takt/Cycle Time: Efficiently schedule work orders based on the line with the shortest Takt Time, optimizing output and productivity across all lines.

Use Line Production Capacity Planner to Improve Throughput

When it comes to tracking production line efficiency, relying on a single data point often falls short. To gain a comprehensive understanding, it's crucial to collect and analyze multiple data points. Our Line Production Capacity Planner empowers you to do just that, enhancing your ability to improve throughput and optimize production.

Line Overall Efficiency Dashboard

The Overall Equipment Effectiveness (OEE) serves as the heartbeat of any successful manufacturing operation, driving efficiency, productivity, and profitability. With the dashboards available in our smart production software, you can unlock your manufacturing potential by monitoring line status, increasing production line capacity, and optimizing resource utilization.

- Monitor Line Status: Minimize downtime and lead times, ensuring on-time delivery and swift response to customer demand.

- Increase Production Line Capacity: Boost output, reduce costs, and enhance product quality by improving the efficiency and effectiveness of your production lines.

- Utilization by Production Line: Identify the optimal balance between resource utilization and line output, driving productivity and operational excellence.

Transforming your shopfloor landscape across all manufacturing sites into a unified production hub empowers you to optimize performance, improve efficiency, and drive success. By utilizing our advanced MES and leveraging real-time data insights, you can make data-driven decisions, proactively address issues, and unlock your manufacturing potential.

Unlocking Clarity and Control: The Power of Real-time Manufacturing Site Dashboards. Check Site and Line Dashboards here.

Real-time Manufacturing Site Dashboards

Continuing our exploration of optimizing manufacturing operations, real-time manufacturing site dashboards provide a centralized monitoring solution. With our Smart Manufacturing Platform, you can monitor all lines and sites seamlessly, enabling data-driven decision-making and improved operational efficiency.

- Customizable Dashboard: Our centralized monitoring system offers customizable dashboards that allow you to quickly identify issues and gain insights for informed decision-making. Tailor the dashboard to display key performance indicators (KPIs) and metrics that are most relevant to your manufacturing sites.

- Real-time Failure Alerts: Receive instant alerts for equipment failures or deviations in real-time. By promptly addressing these alerts, you can prevent costly downtime and maintain the quality of your production output.

- Cross-site Analysis: Compare data from multiple manufacturing sites to identify best practices, optimize processes, and reduce costs. With cross-site analysis capabilities, you can uncover insights that help upgrade operations, standardize procedures, and drive continuous improvement across your enterprise.

By leveraging real-time manufacturing site dashboards, you gain visibility into your operations, enabling proactive monitoring, swift decision-making, and the ability to drive improvements at each site.

Unleash Your Potential: Strategies to Skyrocket Production Capacity Across the Manufacturing Enterprise. Check how If Else Cloud provides real-time insights.

Improve Production Capacity across the Manufacturing Enterprise

Building upon our previous discussions, the key to improving production capacity across the manufacturing enterprise lies in gaining real-time insights into multiple manufacturing sites. With our centralized Manufacturing Execution System (MES) platform, you can optimize production, reduce downtime, and enhance overall efficiency. Elevate your manufacturing game with our NextGen MES solutions.

Real-time Factory Line Monitoring

Gain real-time data on all sites and production lines, enabling better decision-making and proactive management. With comprehensive visibility into production activities, you can monitor key metrics, identify performance trends, and take immediate action to optimize operations.

Production Management Solution

Enhance production management across multiple sites with our MES platform. Identify bottlenecks, inefficiencies, and areas for improvement to maximize production output and efficiency. By leveraging real-time data and insights, you can implement targeted strategies and drive continuous improvement.

Reduce Downtime

Minimize costly downtime by leveraging proactive alerts and predictive maintenance capabilities. Our MES platform provides real-time notifications for potential issues, allowing you to take preventive measures and ensure smooth production operations. By reducing unplanned downtime, you can maximize production capacity and minimize losses.

Quality Control

Maintaining consistent quality control across all manufacturing sites is essential for customer satisfaction and brand reputation. With real-time monitoring capabilities, you can ensure adherence to quality standards and quickly identify any deviations. By addressing quality issues promptly, you can optimize product quality and customer satisfaction.

Lean Manufacturing Platform

Optimize resources and reduce waste across multiple sites with our Lean Manufacturing Platform. By analyzing cross-site data and insights, you can identify opportunities to upgrade processes, eliminate inefficiencies, and reduce costs. Embrace lean principles and drive operational excellence throughout your manufacturing enterprise.

Improving production capacity across the manufacturing enterprise requires leveraging real-time insights, optimizing production management, minimizing downtime, ensuring quality control, and embracing lean manufacturing practices. With our centralized MES platform, you can unlock the full potential of your manufacturing operations, maximize efficiency, and drive success

Real-time Production Data Points.

Take the next step to digitalize your site!

Shopfloor Management Solution for Industry 4.0

Production Workflow Management for Shopfloor

Manage All Your Production Sites with a Unified Manufacturing Solution

Continuing our exploration of manufacturing optimization, managing multiple manufacturing sites and production lines becomes effortless with our Unified Manufacturing Solution. Empowered by real-time data and unprecedented visibility, you can make informed decisions and optimize your processes for maximum efficiency.

- Real-time Analytics: Gain real-time visibility into critical data, empowering you to make data-driven decisions and respond quickly to changing production conditions. With real-time analytics, you can monitor key performance indicators (KPIs), identify trends, and take proactive actions.

- Machine Learning and AI: Unlock the full potential of your manufacturing operations with the power of machine learning and AI. By harnessing these technologies, you can optimize operations, improve agility, and drive continuous improvement throughout your production sites.

- Big Data Platform: Boost profitability and optimize operations with data-driven insights. Our Big Data platform enables you to collect, analyze, and leverage large volumes of manufacturing data to gain valuable insights, identify patterns, and make strategic decisions.

- Modern MES Platform: Transform your manufacturing operations with an innovative Manufacturing Execution System (MES) solution. Our modern MES platform provides a centralized hub for managing all your production sites, streamlining processes, and optimizing performance.

Managing all your production sites with a unified manufacturing solution empowers you to maximize efficiency, drive continuous improvement, and stay ahead in the competitive landscape. By leveraging real-time data, machine learning, AI, and a modern MES platform, you can optimize your operations, boost profitability, and achieve manufacturing excellence.

Contact IfElseCloud to manage all your production sites in one place.

If you're looking for a reliable and comprehensive solution to manage all your production sites in one place, look no further than IfElseCloud. With our expertise in manufacturing management and our advanced technology platform, IfElseCloud offers a seamless and centralized approach to optimize your operations.

By partnering with IfElseCloud, you gain access to a robust system that enables you to oversee and manage all your production sites effortlessly. Our smart factory platform provides real-time data and insights, empowering you to make informed decisions and optimize your processes for maximum efficiency. From monitoring key performance indicators (KPIs) to identifying bottlenecks and optimizing resource allocation, IfElseCloud's solution ensures you have full control over your manufacturing operations.

Contact us today!